Stop the Rot during ZAWAFE 2023 Zambia – 2/4

This blog is part of a four-part series covering the presentations given at the 11th Zambia Water Forum and Exhibition. The event, themed “Accelerating Water Security and Sanitation Investments in Zambia: Towards Agenda 2023 through the Zambia Water Investment Programme”, lasted three days.

Our blog series takes a focused look at the presentations and discussions that revolved around “Addressing Rapid Hand Pump Corrosion in Zambia – Stop the Rot!”, which was co-convened by UNICEF and WaterAid, together with Ask for Water GmbH and the RWSN, hosted by Skat Foundation.

Photo cover: Examples of poor-quality stainless steel

Fourth session:

When stainless steel is not stainless steel

This presentation shares the experience in one of our projects where handpumps were installed with stainless steel riser pipes. On the way, it was learned that there were problems with the quality of the stainless steel riser pipes.

To deal with the issue of hand pump corrosion, various government bodies and donors are moving away from galvanized iron (GI) riser pipes towards PVC river pipes with stainless steel couplings and complete stainless steel riser pipes and couplings.

When using stainless steel, care should be taken in ensuring the right grade and quality is used. If the wrong grade is used, or if coupling are not properly welded, it will still corrode, or break easily. Furthermore, most donors, contractors and consultants in the hand pump sector do not have a background in material science, hence quality of stainless steel may be overlooked. No clear guidelines/standards available for stainless steel hand pump components

Also, there are no clear standards for India Mark II stainless steel handpumps.

Figure 1 shows examples of stainless steel handpump components, which, within half a year were breaking. It is not easy to determine whether stainless steel is of the right quality when it is on-site, but there are some basic tests that can be undertaken. Steel is a mixture of Iron and Carbon (Fe + C), whereas stainless steel is a mixture of Iron, Carbon, Chromium, and other metals (including Nickel and Molybdenum). According to ASTM standards, there are different grades, including Austenitic Stainless Steel Grade 200 and 300 series. We found that 200 Series is not strong enough and that grade 300 Series is stronger and more corrosion-resistant.

Figure 1: Poor quality stainless steel pipe with crack (left) and broken weld (right)

Different grades (based on ASTM*)

The recommended Grade for handpump riser pipes is 304 or 316. However, 304 is less expensive and more commonly used. We have used two tests to determine the grade as follows:

- Spark test: Running a grinder over the alloy, sparks for grade 304 do not fly, they have a reddish-orange tinge appearance and are thin. The grinder test for grade 202 yields thicker, yellow sparks that fly a lot.

- Chemical test using reagent: If the steel turns black then its grade 202, when it turns red but disappears immediately then it’s of grade 304, and if it turns red then its grade 316.

The other important aspect to look for, is how the coupler is welded to the pipe (Figure 2).

Figure 2: Quality of coupling weld – poor weld (left) and good weld (right)

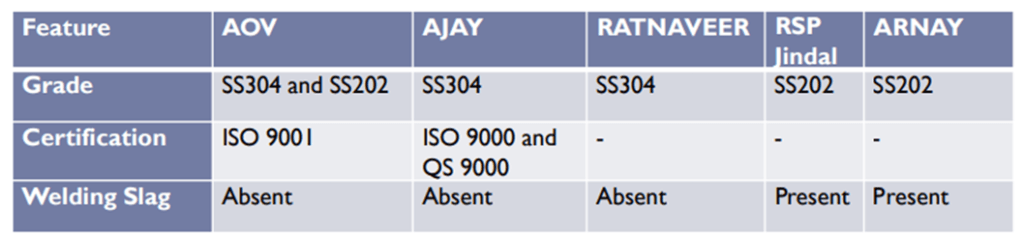

Excess, rough welding slag will be subject to more corrosion. Also in poor quality pipes, the welding slag can be seen clearly in the inside of the pipes. This is a point of corrosion. The project also encountered different quality of stainless steel threads. Different suppliers were also found to be able to provide different levels of certification of their materials. Notably, at the time of the project, not all suppliers were providing stainless steel grade 304, as this was also not clearly specified in their contract.

Brands of Stainless Steel

Figure 3: A selection of brands encountered in Zambia

Looking ahead, it is recommended:

- To include clear specifications on required stainless steel riser pipes in contract, recommending at least grade 304

- To specify on-site test procedure of stainless steel in contract

- Contractors are required to provide quality test certificates of the procured riser pipes.

- Alternatively: Client to procure handpump components directly to avoid low quality materials due to competitive environment

- To RWSN to develop handpump specifications for stainless steel components

- To conduct study to identify cost effectiveness of stainless steel riser pipes versus uPVC riser pipes with stainless steel couplings

You are invited to access the presentations HERE, along with the session’s concept and the study report: Nkhosi. J and Danert, K. (2023). ‘Stop the Rot: History of the Rapid Handpump Corrosion Problem in Zambia and Potential Next Steps. Action research on handpump component quality and corrosion in sub-Saharan Africa’. Ask for Water GmbH, Skat Foundation and RWSN, St Gallen, Switzerland. https://doi.org/10.13140/RG.2.2.27489.28006.

If you would like to dive deeper into the enriching exploration of water challenges and solutions through the Stop the Rot initiative, visit this page.

About the author:

Frank Meins, Aquaquest Ltd presenting at ZAWAFE 2023

Frank Meins is a Zambian resident since 2015, born in the Netherlands, and has 10 years of professional experience in various aspects of water management and engineering, gained in the Netherlands and South-Eastern Africa. He holds an M.Sc. in Civil Engineering and Management with a specialization in Water Engineering and Management from the University of Twente, The Netherlands.