Bono and Ahafo Region, Ghana — Ensuring the safety and quality of drinking water supplies is a pressing concern for public health. While urban areas often benefit from established procedures for water quality monitoring, rural regions frequently lack resources and expertise. This article, produced by USAID’s REAL-Water Activity, explores how a rural water innovation is shifting the communal mindset from “water is life” to “safe water is life,” emphasizing the importance of water quality and the heightened expectations for water operators. It also highlights the unique challenge that researchers face in meeting the growing demand for solutions, which often outpaces the rate at which they are able to complete their evaluations. The article elaborates on this “researcher’s dilemma” and its implications.

Tag: Ghana

Addressing rapid handpump corrosion: the story of the Ghana Modified India Mark II

In 1983, I moved to live and work in Ghana – some 40 years ago now. Back then, I was the regional supervisor on the 3000 Well Maintenance Unit in Southern and Central Ghana which was funded by the German Development Service under the Rural Water Supply programme. The project was a pioneer of its time, and included drilling boreholes alongside the installation and testing of handpumps in six of Ghana’s regions, as well as the Nanumba district, Northern Region.

We initially installed India Mark II and Moyno pumps, before dropping the Moyno due to technical problems. However, we soon realised that the India Mark II pumps faced corrosion issues. Investigation and testing (as documented by Langennegger, 1989 and Langenegger, 1994) found that the Galvanised Iron components (rods and riser pipes), when installed in water with low pH, had a propensity to rapidly corrode – leading to discolouration of the water and affecting taste, but also causing the pumps to fail prematurely as the rods broke and riser pipes developed cracks and holes and even fell into the borehole. The envisaged idea of maintenance by communities, with assistance from mechanics who could reach villages by motorcycle, was simply not feasible with such installations. Another significant issue related to corrosion of hand pump parts was the water contamination and bad taste of the water. As a result, the water coloured the food and therefore caused the population to stop using the borehole water and forced them to go back to unsafe water sources

We, therefore, had to seek alternatives. This involved field testing and collaborating with the Materials Testing Institute of the University of Darmstadt.

We looked into replacing the galvanised iron components with stainless steel. To ensure the pipes were light, we considered using 3 – 3.5 mm thick pipes, and used a threading that at the time was used in the drilling industry , known as the “rope thread”. Although Atlas Copco had patented this threading type at the time, it was later manufactured in India after the Atlas Copco design period (patent) ended.

Figure 1: Rope thread (Claus Riexinger)

The pump rods presented some challenges as well, since the AISI Stainless Steel grade 316 that we were using was subject to breakage, including the threaded parts. In collaboration with our partners at the University of Darmstadt, we were able to find ways to make this grade of stainless steel more elastic by adding 2-3 % Molybdenum. Other issues with the rods related to the use of rolled thread, which we learned was more durable than cut thread. Incorporating these materials and techniques, we were able to reduce the rod diameter from 12 mm down to 10.8mm, resulting in lighter rods which did not corrode. The only drawback was that the threads could not be cut in the field, but this was not such an issue, as there was no need to cut them when they were installed, or upon maintenance.

Figure 2: Pump installation (Claus Riexinger)

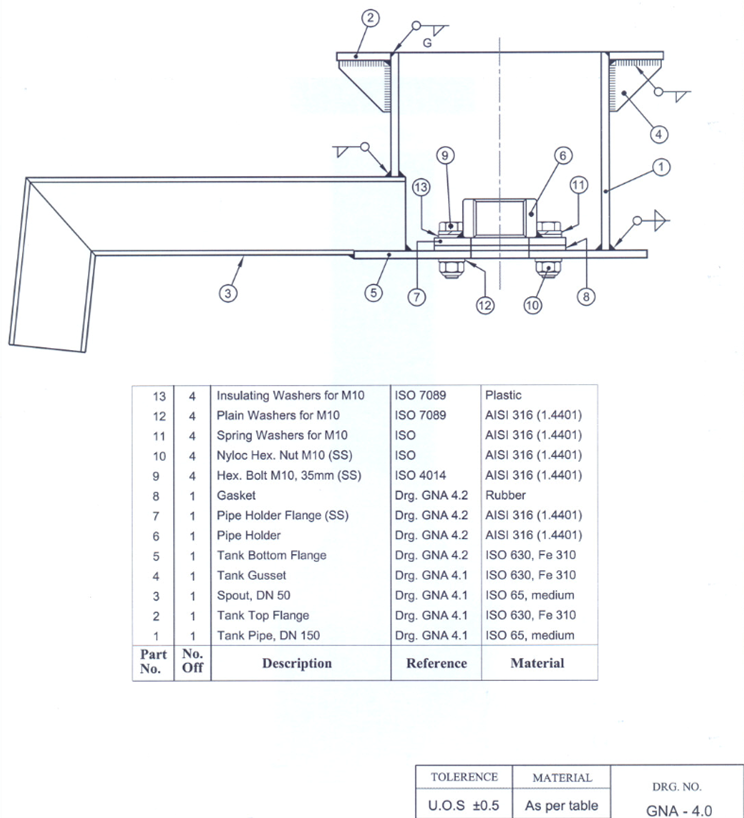

After switching to stainless steel riser pipes, we encountered another issue: -galvanic corrosion between the pipe and the water tank. This type of corrosion occurs when two dissimilar materials come into contact in solution. It was yet another challenge! Fortunately, we were able to solve this problem by replacing the existing flange with a new one made of stainless steel with an insulating gasket, into which the riser pipe could be screwed and prevent any further galvanic corrosion.

Figure 3: Ghana Modified India Mark II Handpump – water tank, spout and flange

After conducting extensive testing and collaborating with the University of Darmstadt over a period of around 4 years, we managed to solve the problem of rapid corrosion of handpumps in Ghana. The improved pump design came to be known as the Ghana Modified India Mark II, and was officially adopted by the Government of Ghana in the 1990s. Its specifications can be downloaded here.

Designing and publishing the specifications for a new pump is one thing, but the other is ensuring that these are adhered to. A series of meetings with government, donors, and NGOs working in the water sector in the 1990s, led to the agreement to no longer use Galvanised Iron. All stakeholders were on board with the change.

Of particular importance was the tremendous support and buy-in of the major donor at the time – KfW (Germany). They agreed to pay for the increased costs of the Ghana Modified Pump on new installations, which at the time was about three times more expensive than the version using Galvanised Iron. KfW also supported the rehabilitation and replacement of the pumps that had previously been installed using Galvanised Iron. As a result, we were able to remove and replace the corroded installations systematically, rather than addressing the issue in a piecemeal manner.

It is estimated that over 4,500 Ghana Modified India Mark II handpumps had been installed in Ghana by the time I left the 3000 Well Maintenance Unit in 1992. Anecdotally, I would say that 90% were working, and of the 10% out of use, they were down for maintenance/repair.

KfW took this design to Cameroon, while Danida took it to Burkina Faso and Zambia. I am not fully aware of what happened next, but I do know that ensuring the quality of stainless steel was a problem in Burkina Faso.

I am very pleased to see that Ghana Modified India Mark II handpumps are now available through the Rural Water Supply Network (RWSN), and hope that these can be of use to other countries that are struggling to overcome the rapid handpump corrosion problem.

Figure 4: Example factory inspection Modified India MKII (Claus Riexinger)

However, I have a work of caution too. Although specifications, standards, and clear procurement documents are essential, they are rendered meaningless in the absence of inspection. During my time with the 3000 Well Maintenance Unit and later as an independent consultant, I traveled to India and other places for pre-shipment inspections. I also oversaw the rejection of consignments from India and Europe due to poor quality or manufacturing mistakes. And so, I urge all of you involved in handpump procurement and installation to make sure that you ensure the quality, especially through inspection and material testing.

Ghana Modified India Mark II Drawings and Specifications

More information about Ghana Modified India Mark II (external website)

About the author: Claus Riexinger is a rural WASH expert and freelance consultant with over forty years of experience in development cooperation with Government organisations, private companies, and development agencies mainly in Botswana, Lesotho, Malawi, Germany, India, Tanzania, and Ghana.

Photo credits: Claus Riexinger

Handpump standardisation in sub-Saharan Africa: Seeking a champion

by Jess MacArthur, IDE Bangladesh

As a millennial, I have to admit: I really enjoy technology and innovation. I love to read innovation blogs and to dissect innovation theory. So just over two years ago as I began researching how innovation intersects development in the world of handpumps, I felt a bit stumped. An estimated 184 million people in sub-Saharan Africa (SSA) today rely on handpumps for their domestic water and many of these use designs that were developed before I was born. Yes, that makes me young and maybe that make you feel old. But mostly, it made me sit back and think. Is this beneficial or is this concerning? At the time I was helping Water4 navigate the policy-sphere around new handpump integration. I wanted to know why certain handpumps have more dominance in certain areas and how innovators can pilot in the sector with both evolutionary and revolutionary designs.

Continue reading “Handpump standardisation in sub-Saharan Africa: Seeking a champion”

4 lessons about handpump sustainability in Ghana

By Sara Marks, Senior Scientist at Sandec / Eawag

In 2012 we learned the exciting news that the Millennium Development Goal (MDG) for drinking water access had been met, nearly 3 years ahead of schedule. Yet an important question still looms large: What will it take to ensure that those who have gained access continue to enjoy their water services well into the future? And how will sustainable water services be extended to the remaining unserved?

Continue reading “4 lessons about handpump sustainability in Ghana”

Cautiously optimistic

More useful analysis from the Triple-S team

What will it take to create WASH sectors that work?

By Patrick Moriarty, Harold Lockwood, and Sarah Carriger

Over the past few months in a series of posts we’ve been advocating for a change in the goal of the WASH sector – from increasing coverage to delivering a service over the long haul; from simply building infrastructure to building infrastructure and managing it into the future to provide services worthy of the name.

And we’ve been calling for a change in approach — from piecemeal projects to strengthening the whole system that delivers services.

We’ve shown how we’ve gone about supporting this type of change in Ghana together with the Community Water and Sanitation Agency, and we’ll continue posting examples from other countries where we’re working.

For now, in the final post in this series, we’d like to talk more about what committing to this change calls for from…

View original post 1,722 more words

Changing the whole system to provide water, sanitation and hygiene services that last

By Patrick Moriarty and Harold Lockwood –

For the last six years or so, primarily through our WASHCost and Triple-S initiatives, IRC has engaged deeply with the challenges of what it takes to provide sustainable water, sanitation and hygiene services. We think that we’ve identified many parts of the puzzle (and so have many others working in the same direction – we’re keenly aware that we’re not the only show in town) and we’ve been sharing these regularly through our websites, papers and blogs. But, what does it take for these piecemeal findings to be taken up and to lead to wholesale change: ensuring that the post-MDG goals of universal access with sustainable WASH services can be achieved by 2030?

View original post 1,251 more words

Who serves the in-betweeners?

By: Marieke Adank, IRC

Small towns and peri-urban areas are by definition found in the grey area in between the truly urban and the truly rural. Also in terms of water supply, fifty shades of grey are found in these types of settlements. People living here often fall in between the cracks of urban utilities and rural water committees. Their water supplies have characteristics of both these service delivery models – though not necessarily the best of those two worlds.

View original post 578 more words

Users perception of rural water services in Ghana: A case of satisfaction or dissatisfaction?

By: Tyhra Kumasi, Senior Research Officer, Triple-S Ghana

Dora is a 33 year old teacher living in Agbedrafo in the Akatsi South District. She depends on the only handpump in the community for her daily domestic chores; however she laments the difficulties in getting access to fetch water. According to Dora “even though fetching is on a first-come-first-serve basis, people bring very big receptacles and containers that makes it difficult, if not impossible, for others to get the opportunity to fetch. Because of this I am sometimes unable to fetch enough. In such a situation I borrow from a neighbour and replace later”. The problem with the borehole is that, after fetching the first few buckets it becomes difficult and hard to pump, one has to wait for a while, about 15 minutes to resume pumping for water. This is worse in the dry season, when she has to…

View original post 1,274 more words

Planning for impact

A very useful update on the Triple-S project

By Patrick Moriarty

Back in June and July of 2012, Triple-S underwent a mid-term assessment (MTA) by an excellent team led by Dr. Ben Ramalingam. The MTA was a hugely useful exercise, allowing the Triple-S team and our partners to take some time out from our day to day work to reflect on how we were doing. The MTA team held up a mirror to us as a project and process – in much the same way that Triple-S seeks to hold up a mirror to the rural water sector – allowing us to have a long hard look at ourselves.

View original post 397 more words

Understanding the Technology Assessment Framework (TAF)

Update on WASHtech

WASHTech, THE project (2011-2013)

“Let’s invite WASHTECH to apply the TAF tool on this Household Water Treatment and Storage (HWTS) technology, the communities choices system, to determine whether it needs to be scaled up”. This came up at the 26th edition of the National Learning Alliance Platform meeting, which recently took place in Accra on theme, Household Water Treatment and Storage Strategy in Ghana.

Members of the WASHTech learning alliance at the meeting had to respond by further explaining and updating stakeholders on the project and the TAF. Abu Wumbei of the WASHTech Ghana team explained that the TAF was indeed a tool that could be used to assess the said HWTS technology, but that the tool was currently being tested on some selected technologies; and that these will enable the fine-tuning of the tool to suit the local situation and context. Thereafter, according to him, the tool will be in full operation; owned…

View original post 308 more words